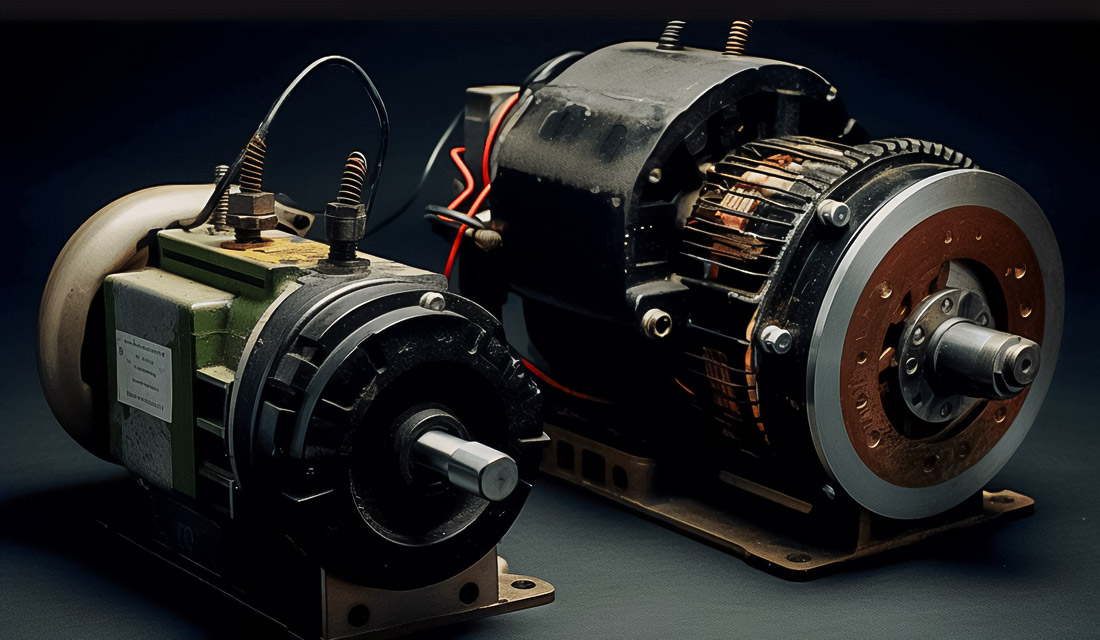

Predictive maintenance has become an essential tool for managing industrial assets. Unlike the preventive approach, where fixed schedules are the basis, the modern strategy uses real time data. The sensors of the IOT record vibration, pressure, and temperature parameters, and machine learning processes arrays of information, highlighting hidden patterns. This approach allows you to predict the moment of a breakdown and plan repairs in advance. This is not just a technical measure, but a step towards a complete restructuring of production thinking. For an electro mechanical company, such methods are especially valuable because they help maximize the performance and lifespan of critical assets.

Table of Contents

Methods and Technologies

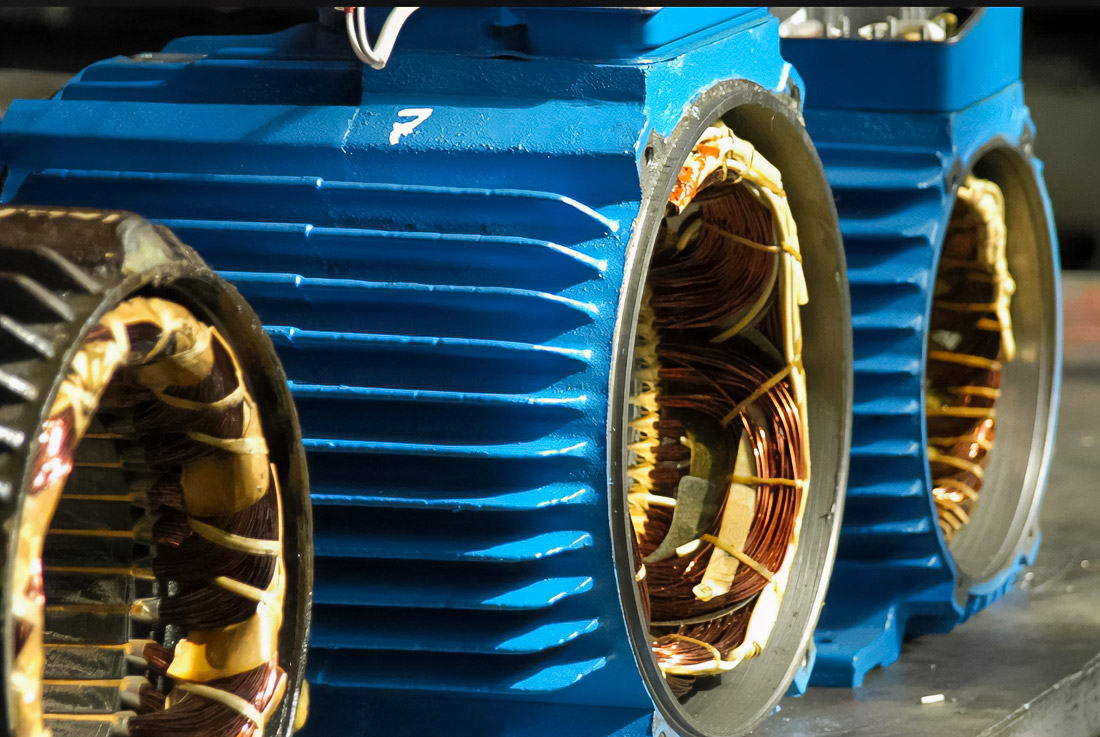

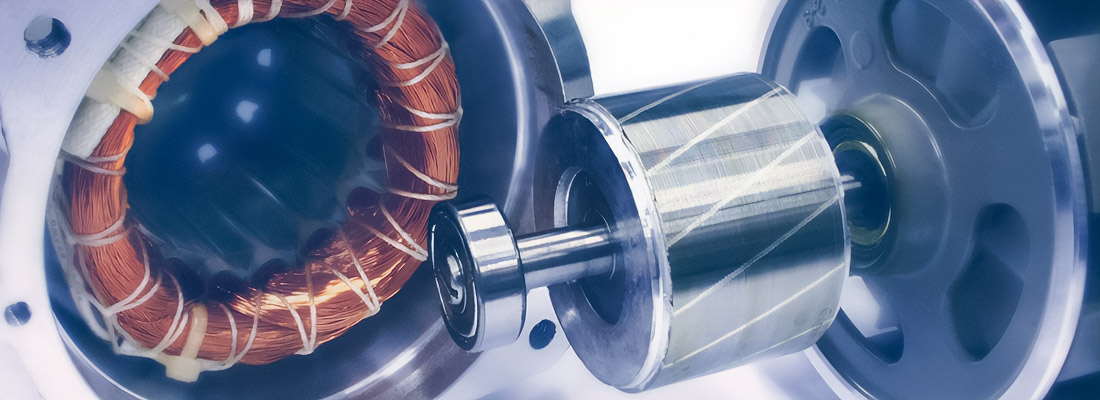

Among the most common tools are vibration monitoring, infrared thermography, oil analysis, temperature monitoring, and fluid analysis. Each of them solves a narrow task, but collectively forms a picture of the condition of the equipment. Overheating control is important in the energy sector, analysis of the condition of drilling pumps and pipelines in the oil and gas industry, and monitoring of engine vibrations in aviation. Electrical testing and circuit analysis help to detect weaknesses in networks in a timely manner. Power system assessments ensure the stability of infrastructure at large facilities. All of this is integrated into the overall condition monitoring system.

Economic and Practical Value

Unplanned downtime is extremely expensive. In the UAE oil and gas sector, for example, the average idle time reaches 32 hours per month. Each hour is estimated at about 220 thousand dollars. The company loses about 84 million a year. Predictive maintenance reduces such risks, providing savings of up to 30% on costs. The number of breakdowns can be reduced by 75%, and downtime is reduced by 45%. The facts confirm that the implementation of such systems justifies even high initial investments.

Sectors and Applications

- Energy: prevention of accidents at power plants, monitoring of networks.

- Neftegaz: control of drilling and transportation equipment, reduction of losses.

- Aviation and logistics: fleet management, reducing the risk of delays.

- Production: reliability of machine tools and robotic lines.

- Construction: monitoring of cranes and building systems.

Implementation and Challenges

Implementing predictive maintenance requires integration with CMMS and ERP as well as staff training. The cost of implementation is high, but the benefits offset the costs. The implementation can proceed in stages: from pilot projects to full automation. Edge computing accelerates data processing, and digital twins improve forecast accuracy. The balance between cloud and on-premises systems is important, as well as data protection. Without this, the implementation will be incomplete.

Predictive maintenance in the UAE has become a strategic focus. It combines vibration monitoring, infrared thermography, oil and fluid analysis to create an early warning system. The economic effect has been confirmed: lower costs, reduced downtime, and increased reliability. The development of a market with a CAGR above 25% and application in key industries show that predictive maintenance is no longer a trend, but a standard. Its role will only increase in the coming years, and the combination of AnchorIoT sensors, analysis algorithms, and cloud platforms will determine the future of the region’s industry.